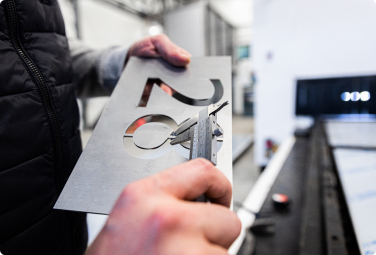

Sheet Metal Cutting

Sheet metal laser cutting

Experience precise laser cutting with fast turnarounds and clean finishes.

At Laser Blade, steel cutting is what we do best. We use CNC laser cutting with Bystronic fiber lasers to deliver every project with speed, high detail and consistency. Whether you’re cutting structural steel, shaping aluminium panels, or producing custom brackets, we have you covered.

Trusted across industries, from construction and engineering to manufacturing and design, our sheet metal cutting service ensures sharp results, zero spoilage, minimal lead times, and installation-ready components.

Fibre lasers with accurate and clean cuts

Suitable for sheets up to 30mm thick

High part output and fast turnarounds

Materials

Mild steel

Stainless steel

Aluminium

Copper

Brass

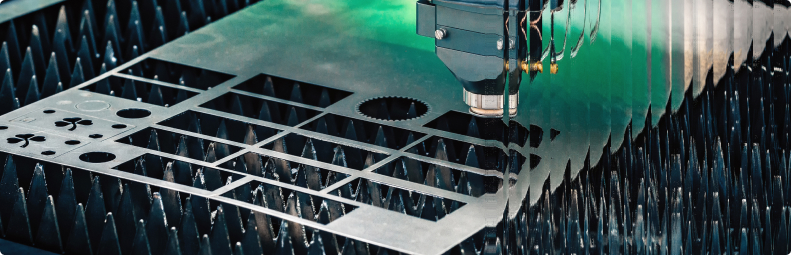

High-Performance Steel Cutting with Bystronic Technology

Powered by Bystronic fiber lasers, our sheet metal laser cutting system was made for efficiency and edge-to-edge accuracy. All our work is done in-house with advanced precision.

Capabilities:

- Bystronic fiber lasers for clean, accurate, repeatable cuts

- Suitable for sheets up to 30mm thick

- Metal cutting for mild steel, stainless steel, aluminium, copper, brass

- High-speed processing with minimal waste and zero burring

- Suited to both high-volume runs and one-off precision projects

- Clean, dry output, no curing, warping, or excess handling required

- Ideal for construction, fabrication, shopfitting and engineering projects

Need tubes or structural round profiles cut? Explore our laser pipe cutting services.

Our Metal Cutting Process

1. Quote & Ordering

Once you submit your file (DXF, DWG, PDF), our team reviews your job for cut paths, nesting efficiency, and material suitability. We’ll send you a quote within 24 hours and flag any file adjustments upfront before cutting sheet metal.

Want to test a prototype before we scale production? No problem.

- Rapid quote turnaround

- DXF/DWG compatibility

- Support for file setup and nesting

- Design tweaks handled in-house

- Consultation available for customisation or prototypes

- Clear communication at every step

2. Materials & Sourcing

We keep a wide range of sheet stock on hand, from standard structural grades to specialised alloys. If it’s not in the rack, we’ll source it fast.

Available materials for steel sheet laser cutting:

- Mild steel (various grades)

- Stainless steel

- Aluminium

- Copper

- Brass

Our network of local suppliers helps ensure availability and reduce delays. Looking for something specific? Just ask, we can help secure unique thicknesses or grades on request.

3. Production & Quality Checks

Every job goes through multiple stages of verification. We validate dimensions, edge quality, and finish consistency before dispatch.

- Job-specific machine programming

- Precision setup with advanced fiber laser cutting software

- Edge deburring if required

- Tolerances maintained through real-time monitoring

- Post-cut QA for measurements, finish, and cleanliness

Once approved, your parts are prepared for pickup or delivered through our trusted freight network. From Yatala, we efficiently service clients for laser cutting in Brisbane throughout Queensland and Gold Coast.

flexible laser

cutting solutions

material

supply available

fast lead

times

delivery

coordination

enquire now

enquire now

enquire now

Get Your Quote Today

Looking for laser steel cutting without delays, defects, or complications? Laser Blade delivers reliable solutions with speed and precision – every time.

Let us bring your next custom sheet metal cutting project to life. Reach out now for a fast quote, expert advice, and a solution that fits your timeline.